TECHNICAL FEATURES

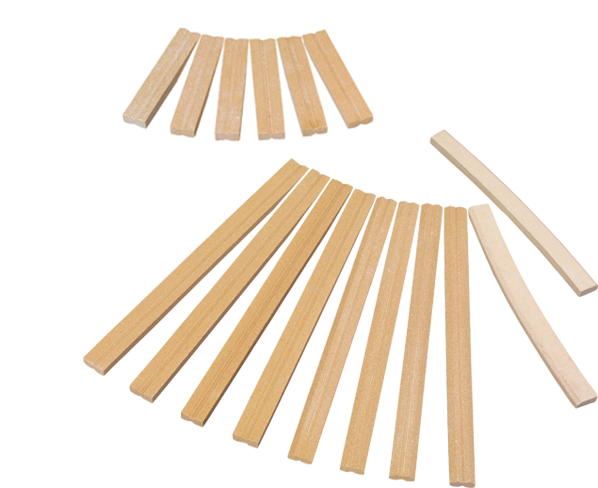

EXTRUDED CORDIERITES

| RPA - MC17A | RPA - MC-19 | RPA - MC-20 | |||

| MINERALOGICAL ANALYSIS | PHASE | CORDIERITE | CORDIERITE | CORDIERITE | |

| CHEMICAL ANALYSIS | Al203 | % | 43 | 43,5 | 42,5 |

| Si02 | % | 45 | 44,5 | 45,5 | |

| MgO | % | 7,0 | 7,0 | 7,5 | |

| Fe2O3 | % | 1,9 | 1,7 | 1,5 | |

| APPARENT DENSITY | g/cm3 | 2,0 | 2,0 | 2,05 | |

| WATER ABSORPTION | % | 11 | 12 | 10 | |

| MODULUS OF RUPTURA AT 25??C | Kgf/cm2 | 150 | 160 | 170 | |

| THERMAL EXPANSION | 10 -7 ºC-1 | 16 | 16 | 18 | |

| MAXIMUM WORKING TEMPERATURE | ºC | 1180 | 1200 | 1220 | |

| THERMAL SHOCK RESISTANCE | Excellent | Excellent | Excellent |

NOTE: The above data is for general information and is based on typical process values.

Variations may occur and Refrat??rios Paulista reserves the right to modify them without prior notice.

TECHNICAL FEATURES

MULCORITE EXTRUDED

| RPA - MC30 | RPA - MC37 | RPA - MC47 | |||

| MINERALOGICAL ANALYSIS | PHASE | CORDIERITE | CORDIERITE | CORDIERITE | |

| MULLITE | MULLITE | MULLITE | |||

| SiC | |||||

| CHEMICAL ANALYSIS | Al203 | % | 44 | 43 | 47,5 |

| Si02 | % | 44,5 | 42,5 | 43 | |

| MgO | % | 7,0 | 6,5 | 6,5 | |

| Fe2O3 | % | 1,0 | 0,8 | 0,6 | |

| APPARENT DENSITY | g/cm3 | 2,10 | 2,10 | 2,10 | |

| WATER ABSORPTION | % | 11 | 11 | 12 | |

| MODULUS OF RUPTURA AT 25??C | Kgf/cm2 | 180 | 230 | 210 | |

| THERMAL EXPANSION | 10 -7 ºC-1 | 18 | 20 | 19 | |

| MAXIMUM WORKING TEMPERATURE | ºC | 1280 | 1290 | 1300 | |

| THERMAL SHOCK RESISTANCE | Excellent | Very Good | Very Good |

NOTE: The above data is for general information and is based on typical process values.

Variations may occur and Refrat??rios Paulista reserves the right to modify them without prior notice.

TECHNICAL FEATURES

SPECIAL PARTS BY CASTING

| RPA - F-1M | RPA - F-9 | RPA - F-13 | RPA - F-24 | RPA - F-2 | RPA - F-2M | RPA - F-4 | RPA - F-14 | |||

| MINERALOGICAL ANALYSIS | PHASE | CORDIERITE | CORDIERITE | MULLITE | MULLITE | MULLITE | MULLITE | MULLITE | MULLITE | |

| - | MULLITE | CORDIERITE | CORDIERITE | - |

- |

- |

ZIRCONIA |

|||

| CHEMICAL ANALYSIS | Al203 | % | 43 | 47 | 65 | 49 | 72 | 72 | 75 | 72 |

| Si02 | % | 45 | 44 | 29 | 43 | 27 | 27 | 24 | 19 | |

| MgO | % | 6,0 | 5,0 | 4,0 | 4,5 | * | * | * | * | |

| Fe2O3 | % | 1,5 | 0,8 | 0,6 | 0,6 | 0,5 | 0,5 | 0,5 | 0,4 | |

| ZrO2 | % | * | * | * | * | * | * | * | 7,5 | |

| APPARENT DENSITY | g/cm3 | 2,0 | 2,0 | 2,15 | 2,05 | 2,35 | 2,35 | 2,45 | 2,5 | |

| WATER ABSORPTION | % | 11 | 12 | 14 | 12 | 11 | 11 | 10 | 12 | |

| MODULUS OF RUPTURA AT 25??C | Kgf/cm2 | 140 | 140 | 280 | 150 | 150 | 180 | 100 | 340 | |

| THERMAL EXPANSION | 10 -7 ºC-1 | 22 | 27 | 32 | 26 | 50 | 48 | 50 | 49 | |

| MAXIMUM WORKING TEMPERATURE | ºC | 1250 | 1280 | 1300 | 1300 | 1500 IN THE FLAME |

1500 IN THE FLAME |

1500 IN THE FLAME |

1380 | |

| THERMAL SHOCK RESISTANCE | Excellent | Excellent | Very Good | Very Good | Very Good | Very Good | Very Good | Very Good |

NOTE: The above data is for general information and is based on typical process values.

Variations may occur and Refrat??rios Paulista reserves the right to modify them without prior notice.